Have you ever heard of the dust thief? This thief is born in your warehouse and waits for the right time to attack. He attacks slowly, without notice. He waits for you to turn away and strikes without notice.

When you first purchase expendables for your aircraft maintenance needs, the thief is born. Maybe something changed where you no longer need the material you procured. After several months the thief gets older and begins to steal the cash value of your inventory.

The longer your inventory sits on the shelf, the more money you spend having to maintain it.

Nobody want's this dust thief in their warehouse, me included.

The less you spend on items that could be stowed away for years the more you'll have to fund your operations.

Now who wouldn't want more of that?

JIT Inventory, The Money Saver

Now imagine getting rid of all your unwanted, unused surplus material. You would free up inventory space for the components that matter most, free up staff having to maintain the unused surplus and reduce your holding costs.

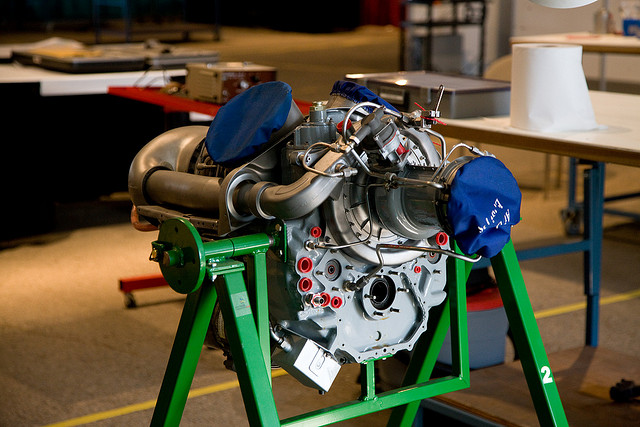

The Just In Time inventory concept allows you to receive expendables as you need them. Since you'll be consuming the material immediately, you'll save thousands on unwarranted spending. Here are the 3 major ways you save:

1. Frees Up Your Inventory - If you have unwanted material taking up space then you'll either have to find additional space for new material or get rid of the excess. If you didn't have excess material taking up space you could down size your warehouse and save thousands on lease payments, mortgages and / or building maintenance costs.

2. Minimize Holding Cost - When you really sit down and think about it, how much does your unused material cost you? Think of the rent for the required space; equipment, materials, and labor to operate the space; insurance; security; interest on money invested in the inventory and space, and other direct expenses. Holding cost adds up doesn't it?

3. Eliminate waste - Now this can be the most troubling because the dust thief takes your expendables and literally throws them in the trash. Once your life limited expendables and consumables reach their expiration point, they're done. Wasted. The same goes for obsolete components. Once the manufacture comes out with an upgrade, the component is no longer of value to you, even on your shelf.

Managing inventory consumption is a strategy that can save you thousands if done right. Stock the important stuff and take in the expendables and consumables as you need them. The best way to do this is to utilize a JIT inventory system backed by the support of your competent suppliers.

P.S. Would you like to discuss the JIT solution we have ready for you? Click here