Discover three masterful approaches to revolutionize your material planning, ensuring unstoppable reliability in aircraft maintenance.

Reveal 3 Hidden Flaws Sabotaging Your Aircraft Line Maintenance Supply Chain—And How to Fix Them Now!

Uncover the three concealed flaws that might be sabotaging your aircraft line maintenance supply chain, and gain insights on how to rectify them for improved efficiency and reliability.

5 Big Aircraft Maintenance Trends To Seize In 2021

Successful operations are always improving.

They’re not comfortable with “it’s how we’ve always done it.” Complacency destroys operations. A simple fix to a critical process that’s done daily can have a significant impact throughout the year.

Why Used Parts Scarcity Will Negatively Impact Your Operation

What’s one thing that will save you millions of dollars and months of your time?

Used Serviceable Material (USM).

Without them, you’d throw good money after bad, chase long, complicated lead times and get little OEM support, especially for older aircraft models.

That’s why this post is so crucial for you to read.

It’s a trend that has no foreseeable end, unless particular things happen within the aviation industry, of which, none exist.

The trend is, used serviceable parts are becoming more expensive and scarce.

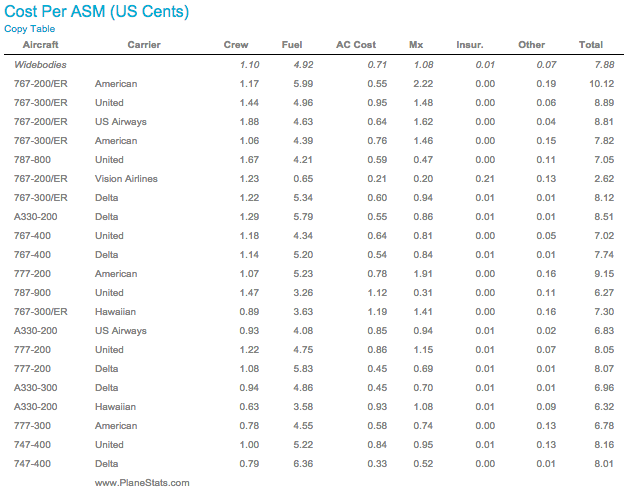

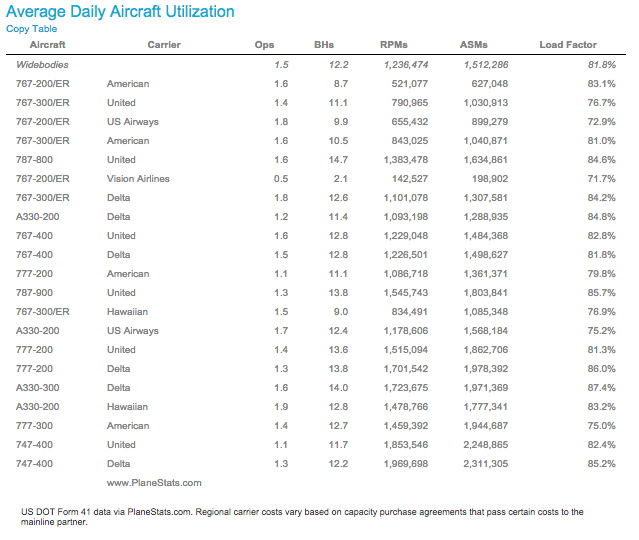

Do You Know Your Wide-body Aircraft Operating Costs?

Whether you own a fleet of regional, narrow-body or wide-body aircraft, knowing your operating costs is important.

Your goal is to lean out and maximize your fleet to it’s fullest potential. What strategies can you adopt to streamline your maintenance costs? With crew and maintenance costs being over 25% of your total operating costs, I would say these are important, wouldn’t you?

Below is a list from planestats.com on the reported aircraft operating costs for nearly 500 wide-body aircraft for the 12 months of 2014. Its good to note that fuel prices will clearly be much different for 2015.